In the intricate world of industrial automation, where precision and efficiency are paramount, understanding industrial protocol communications is crucial. For professionals who have moved beyond the basics, grasping the nuances of these protocols can significantly enhance system performance and interoperability. This blog delves into advanced aspects of industrial protocol communications, shedding light on critical elements that every industry expert should be familiar with.

The Evolution of Industrial Protocols

Industrial protocol communications have evolved significantly over the past few decades. Once limited to isolated, application-specific protocols, they now support a wide range of functionalities including real-time data exchange, process control, and diagnostics. This transformation marks a shift from legacy systems to modern, sophisticated communication frameworks designed to meet diverse industrial demands. Today’s protocols are built for interoperability, scalability, and security—crucial for seamless IIoT integration. As industries move towards smart automation, robust communication standards are more vital than ever for ensuring efficiency and reliability.

What Is an Industrial Communication Protocol?

The industrial communication protocol defines the rules and formats to be used in data interchange across an industrial environment. It facilitates the flow of information from one component within a system to another with accuracy and efficiency. As simple as it may sound to define what an industrial communication protocol is, mastering the intricacies goes with an appreciation of the impact on system architecture and performance.

Advanced Protocols: Key Players in the Industry

- OPC UA (Open Platform Communications Unified Architecture): OPC UA has become a cornerstone in industrial protocol communications, known for its scalability and flexibility. It supports complex data models and ensures secure, reliable data exchange across different platforms. Its ability to integrate with various systems and applications makes it a versatile choice for modern industrial environments.

- PROFINET: A prominent member of the communication protocols used in industrial automation, PROFINET is renowned for its high-speed data transfer and real-time capabilities. It is particularly valued in manufacturing settings where precision and speed are critical. The protocol supports various communication speeds, making it adaptable to different automation needs.

- EtherCAT (Ethernet for Control Automation Technology): As one of the fastest industrial communication protocols, EtherCAT is designed for real-time control and high-speed data transfer. Its efficiency is evident in applications requiring rapid processing and minimal latency, such as robotics and motion control systems.

- Modbus: Despite being one of the oldest protocols, Modbus remains relevant due to its simplicity and ease of integration. It is widely used for communication protocols in industrial automation due to its robust performance in various scenarios. Understanding Modbus is essential for professionals working with legacy systems or hybrid environments.

- CANopen: Designed for embedded systems, CANopen offers flexibility and interoperability in industrial protocol communications. Its ability to handle complex device networks and provide real-time communication makes it suitable for diverse applications, including automotive and industrial machinery.

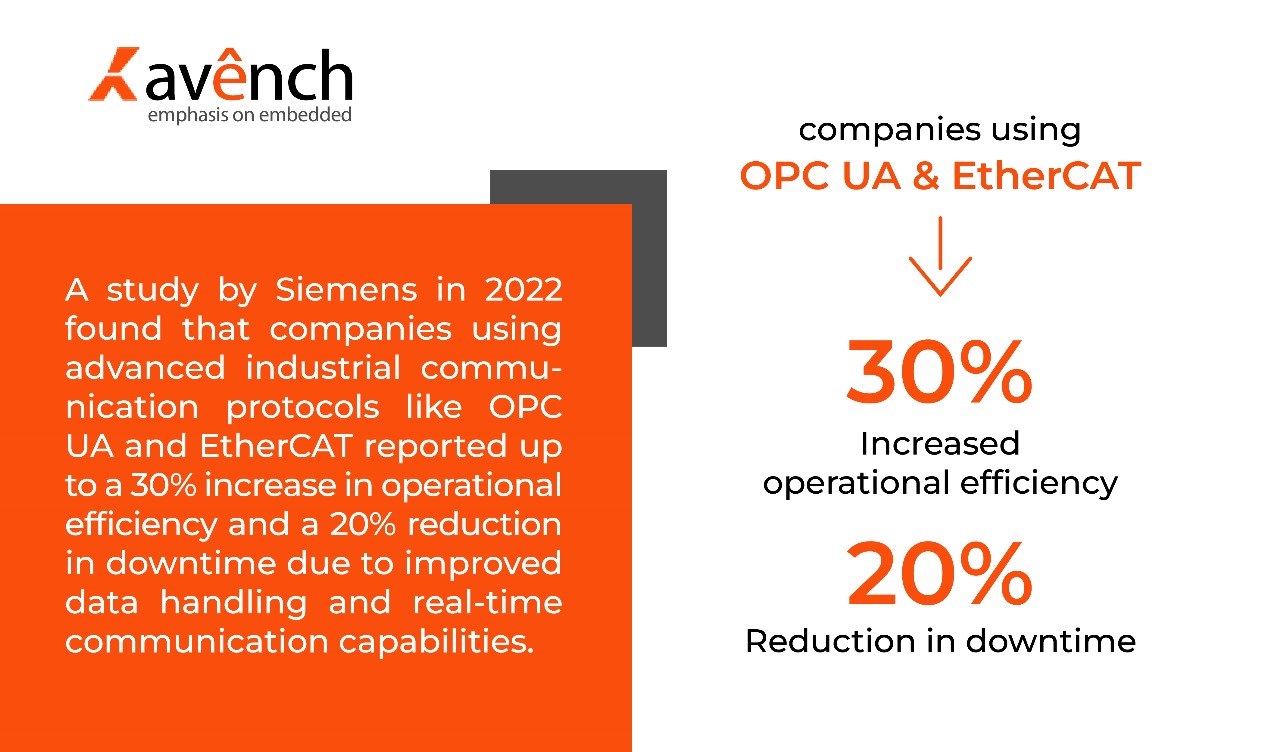

This trend underscores the growing importance of advanced communication solutions in industrial settings.

This trend underscores the growing importance of advanced communication solutions in industrial settings.

Comparing Protocols: Choosing the Right Fit

Selecting the appropriate protocol depends on various factors, including speed, data complexity, and application requirements. For instance, while EtherCAT is unmatched in speed, OPC UA offers superior flexibility and security. Evaluating the most common industrial communication protocols helps in making informed decisions tailored to specific industrial needs.

When comparing industrial communication protocols, consider the following criteria:

- Speed and Latency: High-speed protocols like EtherCAT are crucial for applications requiring minimal delay. In contrast, protocols like Modbus, while not as fast, provide reliable performance for less demanding tasks.

- Data Handling: Protocols like OPC UA and CANopen excel in managing complex data structures and supporting extensive device networks. Their ability to handle sophisticated data models is essential for modern industrial systems.

- Security and Scalability: As industrial networks become more interconnected, security and scalability are paramount. OPC UA, for example, offers robust security features, making it suitable for environments with stringent data protection requirements.

Challenges and Solutions in Protocol Communications

Challenges and Solutions in Protocol Communications

While industrial protocol communications offer numerous benefits, they also present challenges. These include interoperability issues, network congestion, and security vulnerabilities. Addressing these challenges requires a strategic approach:

- Interoperability: Ensuring that different devices and systems can communicate effectively is crucial. Using standard protocols like OPC UA can mitigate interoperability issues by providing a common framework for data exchange

- Network Congestion: High data volumes can lead to network congestion. Implementing efficient protocols and optimizing network configurations can help manage data traffic effectively.

- Security: Industrial networks are increasingly targeted by cyber threats. Employing protocols with built-in security features and implementing additional security measures are essential for protecting sensitive data.Future Trends in Industrial Protocol Communications

The industrial protocol communications landscape is in a continuous process of evolution. Future trends include advanced technologies like AI and machine learning, which hold the promise of further improving the performance and efficiency of protocols. Yet another future trend is Industry 4.0, for which an even greater need is placed on protocols that will allow seamless data exchange among diverse systems and applications.

Conclusion

For the industrial professional, mastering industrial protocol communications means more than mere knowledge of the concept. It is about the depth of the various protocols, their applications, and how they impact the performance of the systems. This keeps one abreast of the latest happenings and trends to be able to power industrial automation based on those protocols in a bid to help create innovation in respective fields. Be it what is an industrial communication protocol, which is the fastest industrial communication protocol, or what is the most common industrial communications protocol, nuances of understanding are important to reap the proper results from industrial communications.

Avench Systems realizes that advanced industrial protocol communications are going to change the face of industrial automation. We integrate and optimize these protocols to give unparalleled efficiency and performance for our businesses. Be it understanding what an industrial communication protocol is, finding the fastest industrial communication protocol, or just getting the list of common industrial communication protocols.

Avench is a leading embedded system companies in bangalore . For any sales queries, contact us at +1 (775) 404-5757. You can also email us at sales@avench.com. We will be happy to assist you.

Challenges and Solutions in Protocol Communications

Challenges and Solutions in Protocol Communications