The field of embedded hardware design has long been seen as highly specialized, with a focus on optimizing performance, reducing power consumption, and ensuring reliability. Traditionally, engineers followed well-established patterns, adhering to industry standards for board layout, component selection, and interfacing with software. However, in recent years, unconventional approaches are emerging, driven by new technology requirements and the need for more efficient, scalable, and adaptive systems. These shifts are not only reshaping the way we think about embedded systems but also pushing embedded hardware design companies to rethink their development strategies.

Rethinking Form Factors and Materials

One of the key areas where embedded hardware is evolving is in its physical form. Conventional designs have often been constrained by the standard dimensions of printed circuit boards (PCBs) and the limitations of traditional materials. However, advances in flexible and stretchable electronics are enabling entirely new possibilities for embedded hardware design projects.

These developments involve materials such as flexible substrates, which allow circuits to bend, twist, or fold without breaking. This can be crucial for applications in wearables, medical devices, and even certain aerospace technologies, where space and adaptability are critical. With these new form factors, embedded hardware becomes more versatile, accommodating designs that fit seamlessly into the human body, vehicles, or cramped industrial environments.

For embedded hardware design services, this shift means thinking beyond the rigidity of conventional components and adapting to a world where hardware needs to conform to increasingly demanding applications.

Open Hardware Platforms: A New Path Forward

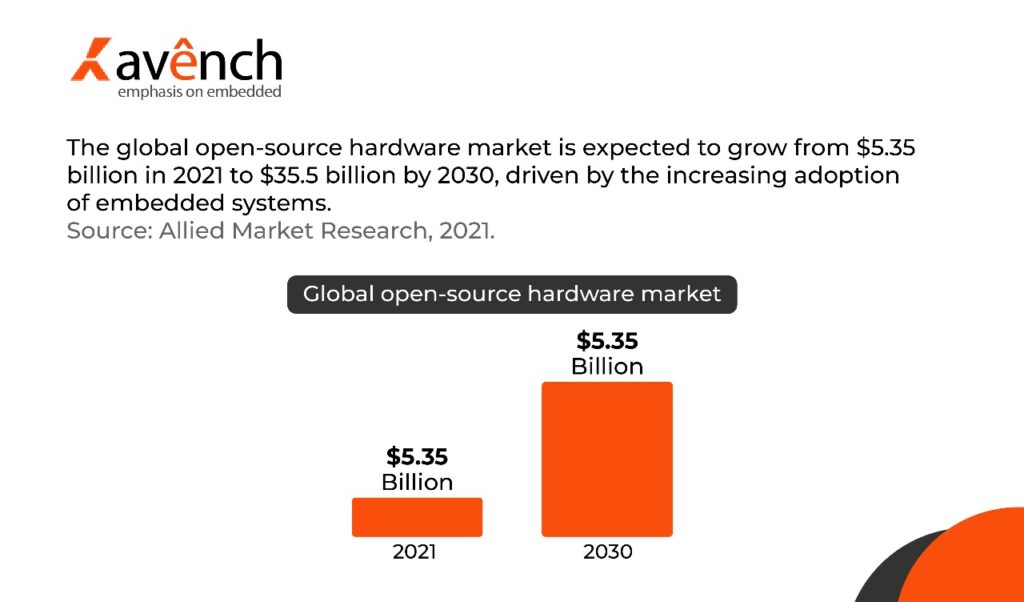

Another significant trend shaping the embedded hardware design & development process is the adoption of open-source hardware platforms. While software development has seen a surge in open-source projects, hardware has been slower to embrace this trend. However, the growing interest in platforms like Arduino, Raspberry Pi, and BeagleBone is changing that landscape.

Open hardware platforms provide pre-designed, modular systems that can be customized for specific applications. This shift is lowering the barrier to entry for startups and smaller embedded hardware design companies, which may not have the resources to develop systems from scratch. By using open hardware, developers can quickly prototype ideas, reducing time to market while ensuring flexibility.

Open-source hardware also enables a collaborative development environment, where engineers can contribute to a shared pool of knowledge. This means more efficient troubleshooting, faster iterations, and an overall improvement in the robustness of embedded systems.

AI and Machine Learning at the Hardware Level

Artificial intelligence (AI) and machine learning (ML) are usually discussed in the context of software, but they are starting to play a role in embedded system hardware design as well. Traditionally, embedded systems relied on predefined algorithms for data processing. But with the integration of AI, hardware is becoming more adaptive, capable of adjusting itself in real-time based on environmental conditions or operational feedback.

Edge computing is a perfect example of where this trend is having a significant impact. Instead of sending all data to the cloud for processing, embedded systems can now handle complex AI tasks locally, thanks to more intelligent hardware architectures. These architectures are optimized to run AI models efficiently, without the need for heavy computational resources.

For instance, in embedded hardware design projects involving autonomous vehicles or smart factories, AI-enabled chips are used to make decisions instantly, reducing latency and improving overall system responsiveness. As AI continues to influence hardware, embedded hardware design services will have to adapt, offering more advanced designs that support these computational requirements at the edge.

Power Efficiency Through Energy Harvesting

Embedded systems have always been designed with power efficiency in mind, particularly for applications where changing batteries frequently isn’t practical, such as remote sensing, medical implants, or IoT devices. Traditional power optimization strategies focus on minimizing energy consumption through low-power states or more efficient algorithms.

However, energy harvesting is emerging as a game-changer for embedded hardware design. By capturing energy from ambient sources like light, heat, or motion, devices can potentially operate indefinitely without external power sources. This capability drastically reduces maintenance costs and extends the operational life of embedded systems in remote or inaccessible locations.

Energy harvesting technology is still evolving, but it holds great promise. As more embedded hardware design companies integrate this technology into their designs, it could fundamentally change the way we think about powering devices in the future.

The Rise of Custom Silicon

Custom silicon, particularly application-specific integrated circuits (ASICs), is gaining traction in the embedded hardware design & development world. Instead of relying on general-purpose processors or microcontrollers, more companies are designing custom chips tailored to their specific needs. This approach allows for greater optimization, both in terms of performance and power efficiency, as the chip is designed precisely for the intended use case.

This trend is particularly evident in high-performance applications such as cryptocurrency mining, AI acceleration, and telecommunications, where standard off-the-shelf components can’t deliver the required performance. Custom silicon can also improve security, as companies can integrate hardware-level protections directly into the chip.

Cross-Disciplinary Collaboration

As embedded systems become more complex, embedded hardware design projects are increasingly benefiting from collaboration across multiple disciplines. Mechanical engineers, material scientists, software developers, and electrical engineers are working together more closely than ever before. This interdisciplinary approach allows teams to tackle problems holistically, considering all aspects of the system, from the physical constraints of the hardware to the software that drives it.

Cross-disciplinary collaboration also opens the door to more innovative solutions, as professionals from different fields bring unique perspectives and expertise to the table. This trend will continue to drive forward the capabilities of embedded hardware design, enabling more sophisticated and integrated systems.

Conclusion,

The embedded hardware design industry is undergoing a transformation as new materials, open platforms, AI integration, energy harvesting, custom silicon, and cross-disciplinary collaboration reshape the field. These unconventional approaches are pushing the boundaries of what embedded systems can achieve, offering more efficiency, adaptability, and intelligence. For companies involved in embedded hardware design services, staying ahead means embracing these changes and rethinking traditional approaches to meet the demands of future applications.

For more information on embedded product design companies in usa subscribe to our blog. For sales queries, contact us at +1 (775) 404-5757 or email sales@avench.com. We are here to assist you.