Embedded Product Development Embraced by Industrial Internet of Things (IIoT)

In this era of fast-track technological evolution, many technologies have been replaced or updated with new disruptive ones. Enterprises need to upgrade to these newer technologies not only to survive, but also to gain a competitive advantage in the markets. The Industrial Internet of Things is revolutionizing industries and transforming the processes. With a huge business potential, IIoT industry service providers and many other companies are trying to provide innovative solutions across industries. Many enterprises both old and modern are appreciating the power and merits of connectivity. With the implementation of new technologies many enterprises are now well connected, and the market is witnessing ever-increasing demand from many end-users for wireless connectivity in both devices/machinery and solutions.

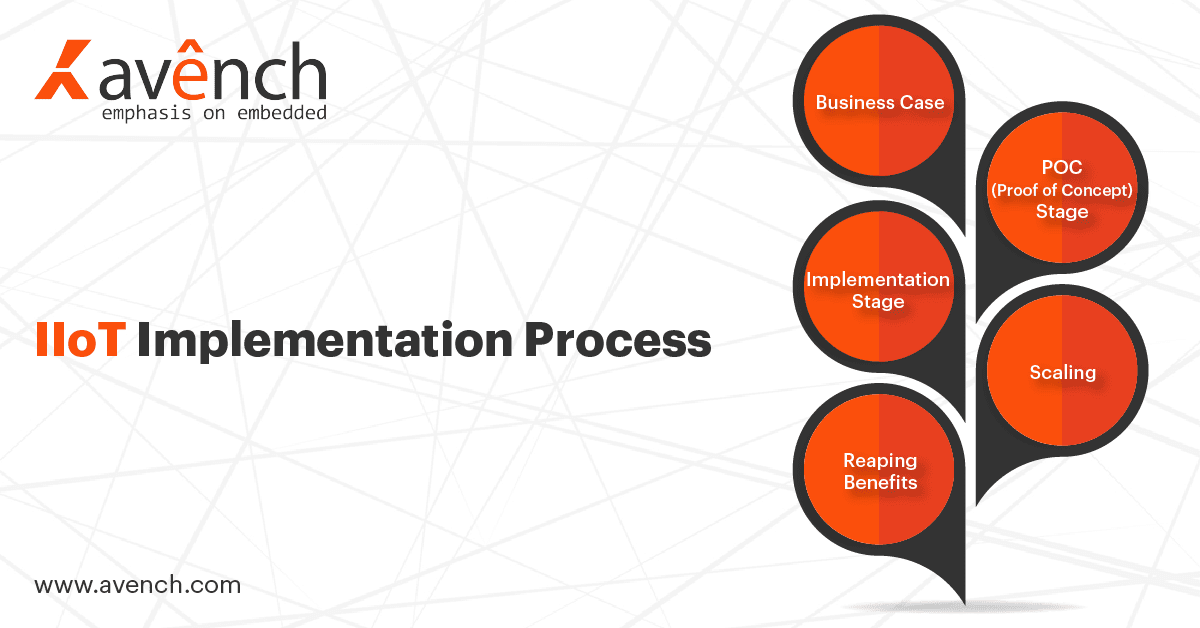

An ideal IIoT Implementation process can be divided into several stages:

- Business Case: Companies focus on the problems in their current scenario and also conclude the value of annual loss that is created by their problem and how well it can be mitigated through IIoT.

- POC (Proof of Concept) Stage: Companies build a proof of concept that helps to understand how well IIoT can bring down their existing issue. They also focus on the challenges and other roadblocks during IIoT implementation.

- Implementation Stage: After careful analysis of the user benefits, challenges, and the scope of IIoT, enterprises implement the (POC) proof of concept in one of the facilities to test on real time basis.

- Scaling: When implementation is successful with one facility and the desired results are visible, the same is scaled up within other facilities across the enterprise.

- Reaping Benefits: After IIoT enablement, enterprises start making gains. With technology integration, maximum benefit can be achieved.

The Impact of IIoT

Many enterprises are ready to derive a plethora of benefits from IoT connectivity and to experience not only flexibility in device management but also the controllingfeatures of the devices. Machine-to-Machine (M2M) communications help to interact, enable real-time asset tracking and performance management.

On the factory floors, IIoT helps in data exchange between machines through devices such as actuators and sensors. Thus, process effectiveness and better efficiency are achieved by reducing downtimes and increasing in DRIFT (Doing things right the first time) machine utilization through robust predictive analytics-based maintenance, fleet management, etc. The sensors that are scattered throughout the manufacturing plant that collect, aggregate, and analyze tons of data help in making sound real-timedecision making, which ultimately contributes to increased productivity.

There is a tremendous rise in the IIoT that has emerged from the need for smarter, faster, and smaller processors that have secured wireless communication and also have efficient power management. Due to the huge advancements in embedded technology, there is a larger use of efficient and compact sensors in the embedded devices that have resulted in the emergence of portable, smarter, and fully operated products.

While Embedded systems form the core technology for enablement of interactions between ‘Things’, IIoT focuses on connectivity between ‘Things’ or devices.

Embedded product development is increasing with a tremendous rise in the demand for IIoT.

Avench is one of the leading embedded companies in the United States. To know more information about embedded product design and embedded systems please subscribe to our blog. For any sales queries, contact us at +1 (775) 404-5757. You can also email us at sales@avench.com – we would be happy to assist you.