Turnkey Manufacturing and its Benefits

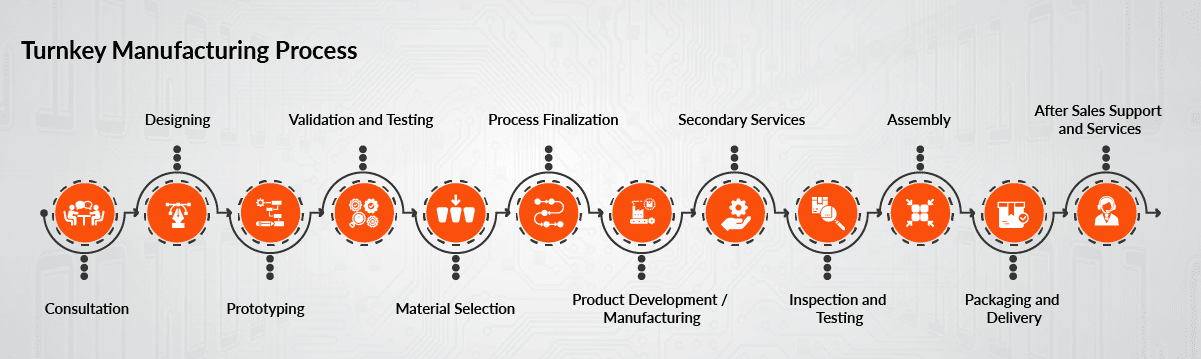

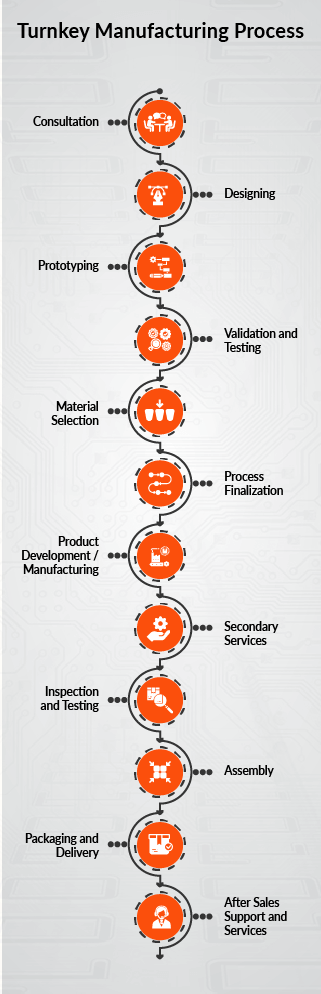

Turnkey manufacturing is where one company carries out the entire process from design to production and sales of your product. The stages of the process include the initial design phase, manufacturing, quality assurance, packaging, and shipping. Such companies are leaders in manufacturing and are known as a third-party partner or a contractor who takes end-to-end responsibility for the project.

Some of the companies may prefer to work in either partnership with a turnkey manufacturing company that provides designs, layouts, and purchase of new equipment or may choose to integrate with their existing equipment.

Enterprises prefer turnkey electronic manufacturing because it helps create the opportunity for the enterprise to focus on their core business areas such as marketing & sales and R&D instead of spending time and investment on updating machinery, improving manufacturing efficiency, and updating/optimizing technology processes. An added advantage of opting for a turnkey manufacturing model is that you can meet the demands of the market without worrying about scaling the current in-house manufacturing capacity.

Companies also benefit from turnkey services where they outsource certain projects as they may not have the in-house production capacity/capability. The benefits of turnkey manufacturing go beyond streamlined communications and cost-savings. As the partner, not only provides supply chain and manufacturing services but also services such as installation, technical support service and after sales support just to name a few.

Key Benefits of Turnkey Manufacturing.

- Single Point of Contact – Tracking the progress of your project with one company is more simple and quick than coordinating and managing multiple vendors/partners. Furthermore, an ideal turnkey manufacturer eliminates the problems in communication. For example, instead of communicating with your designer, manufacturer, and all other related partners / vendors, it is simple for you to contact only the turnkey manufacturer as they take care of everything end to end.

- Collaboration between Design and Manufacturing – If you have any changes in mind for your project i.e for example to add a feature or suggest any further changes, it is possible and easy to get it swiftly implemented with the turnkey manufacturer then coordinating with different designing and manufacturing partners.

- Improved Quality – When a single company owns and handles the entire product development to manufacturing lifecycle right from the concept to completion, it is simpler to expect a product of higher quality as all the gaps in coordination, communication and collaboration are eliminated. Right from the idea to completion, a turnkey manufacturer can set the level of quality needed for your respective project.

- Economy – Working with a single partner streamlines the process and you can cut costs and negotiate for better discounts as well. Furthermore, the turnkey model helps you to save many costs related to payroll as you don’t need multiple in-house resources to manage the project.

Avench systems is one of the leading embedded systems manufacturing companies in the United States, and it helps in manufacturing embedded systems and developing embedded software across various domains and industries. For any sales queries regarding embedded systems manufacturing and embedded software development wait for no further, contact us at +1 (775) 404-5757. You can also email us at sales@avench.com and we would be happy to assist you.