The designer does not begin with some preconceived idea. Rather, the idea is the result of careful study and observation, and the design a product of that idea. – Paul Rand

The embedded product design Cycle is the assemblage of commonly identified stages in the life of commercial products. The stages which a product cycles through during its lifespan are: Concept, System Architecture, Hardware Design, Software Development, Product Prototyping, and Testing. It concentrates on the outlining, development and evaluation of a product and studies the execution of the product in the market.

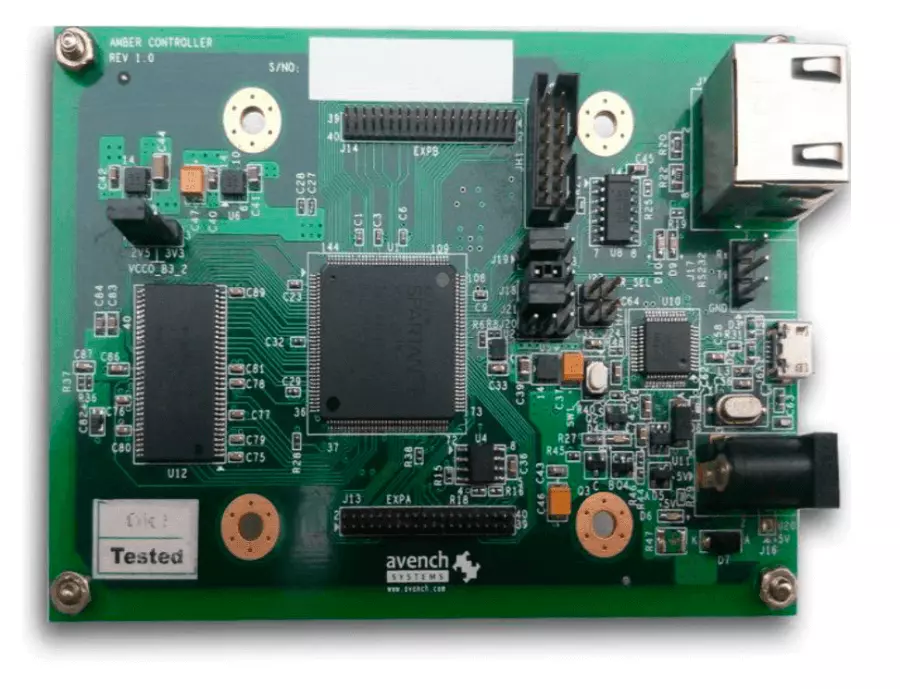

Embedded product design is an essential part of the electronics equipment that requires specialized software, significant tools, and skilled engineers to design. Right from medical to industrial electronics, consumer to military electronics, and from industrial automation to telecom & datacom; defense & aerospace, every device that we design is unique in functioning. Avench offers a plethora of embedded product designs for various industrial and non-industrial needs.

The versatility of our offerings

- Our talented team enables us to provide innovative embedded firmware and software services.

- By understanding the specific and exact needs of the system level programming, we suggest an appropriate platform that will help optimize product cost, performance and design.

- We offer end-to-end embedded product design solutions globally

We assist product development companies and original equipment manufacturers by focusing on cost advantage. Avench is your ideal choice in the USA because it provides complete embedded design services straight from concept to deployment with focus on detail along with excellent design practices. Embedded Product Design offers technical feasibility, embedded product development and innovation, engineering analysis, and prototyping.

Typical Product Design Cycle

-

Concept

-

System Architecture

-

Hardware Design

-

Software Development

-

Product Prototyping

-

Testing

Avench's Approach

At Avench, we deep dive into the embedded product design cycle. Starting from the ideation of the project, we provide an elaborate method of working until the support of the said project. We assist you in knowing the feasibility of your project, which in turn helps you understand the project’s technicalities and its achievement. We provide you with the Statement of Work(SOW) which gives you the project’s detailed features.

Avench’s approach towards the execution of the project is structured and helps you in finalizing the engagement model and Project Management methodology. Next, the industrial designing step helps you to understand the overview of the product’s look and feel, with technologies of 3D model development, enclosure prototyping, evaluation and debugging, and 3D model development for mass production. Then, we proceed to a hardware design that involves block diagram, critical component selection, schematic capture, PCB Layout design and Gerber generation, PCB fabrication, final assembly of the product and then the product is brought up for testing. Post designing the hardware architecture of the product, we move to software designing. This step includes high-level architecture, processor and peripherals selection, Programming approach finalization, System software development, Firmware development, Application development, Code optimization, and Testing.

Once the designing process for hardware and software is completed, we proceed to Integration testing where the working of the product is determined. Then, we proceed to prototype and manufacturing. While working through all these processes and steps, we provide you with continuous support before, during and after the completion of the project.

Avench has a unique and structured way of designing embedded products which helps the customers in gaining the detailed insights of the project footprints and support them with anything at any stage.

Avench Product Design

Ideation

Technical Feasibility

SOW Finalisation

Approach

Engagement model selection Finalization of PM methodology

Industrial design

3D model development Enclosure prototyping Evaluate and debug 3D model development for mass manufacturing

Hardware design

Block diagram Critical component selection Schematic capture PCB layout design and Gerber generation PCB fabrication Final assembly Board bring up and testing

Software design

High level architecture Processor and peripherals selection Programming approach finalization System software development Firmware development Application development Code optimization Testing

Integration testing

Prototyping

Support

Knowledge transfer IP transfer Maintenance support Support for mass production

What makes us different?

Detailed Market Research

Experienced Development Team

Technical Support

Timely Execution