Top 6 Practical Applications of IIoT in Industrial Automation

What is Industrial IoT?

The Industrial Internet of Things IIoT in industrial automation is about interconnected controllers, sensors, and other devices networked together in an industrial setting. This type of connectivity allows for remote monitoring, access and more importantly allows for data acquisition with collection, exchange, and analysis of multiple data sources.

IoT in industrial automation has tremendous potential and benefits for reducing costs, improving productivity, and increasing efficiency. IIoT solutions are characterized by their fast implementation and low cost.

IoT in Industrial Automation

Industrial automation aims to increase productivity, provide optimum cost of operation, improve product quality, reduce routine checks and raise the level of safety. embedded systems for Industrial automation includes the usage of data-driven control systems such as PLC controllers or robots and industrial computers that help in reducing the need for humans operating machinery. IoT applications are increasing and play a vital role in industrial automation. IIoT creates systems that are affordable, effective, and flexible to customer needs.

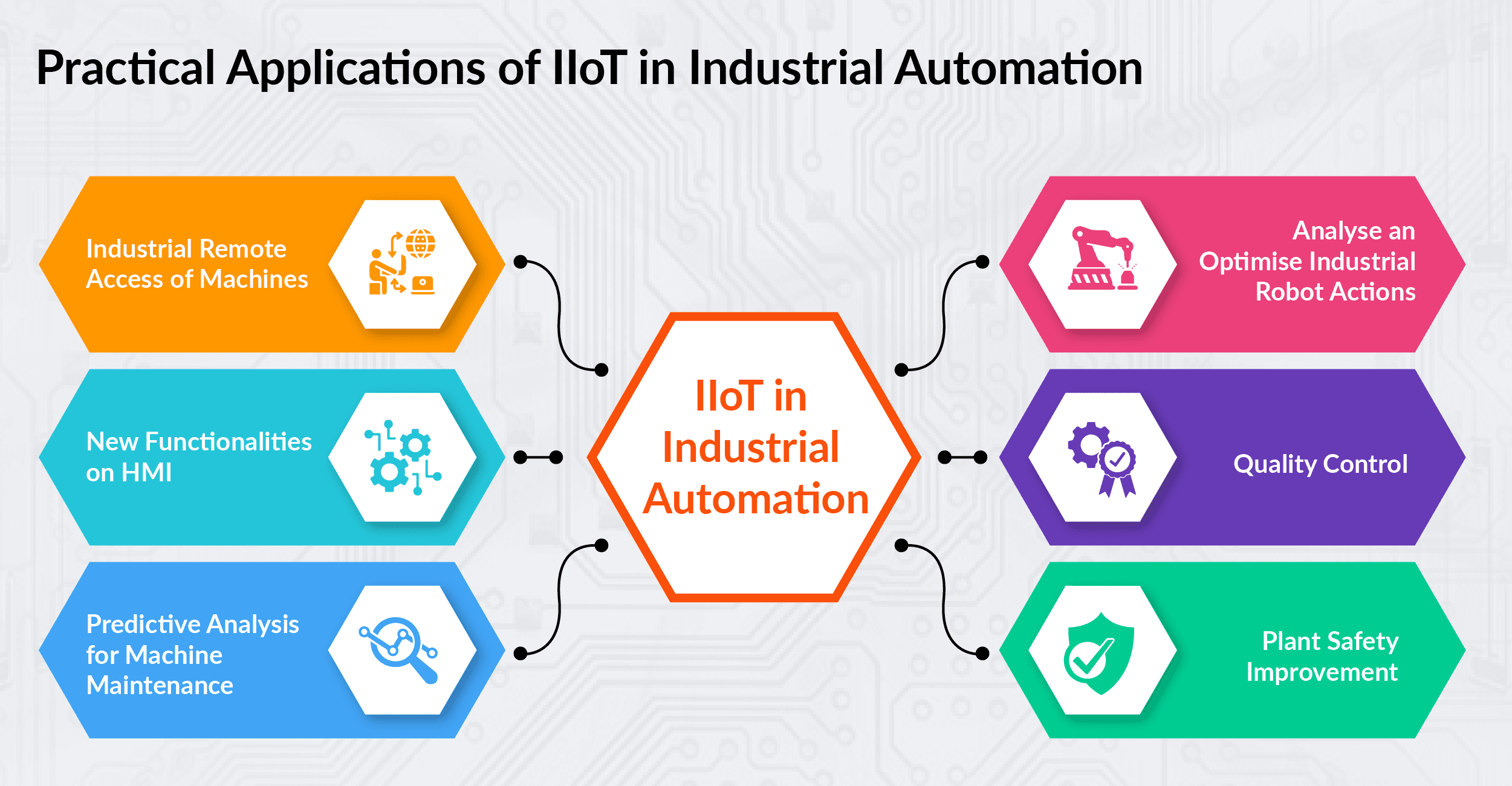

Practical Applications of IIoT in Industrial Automation:

-

4o

Avench is one of the leading offshore embedded firmware development company in Bangalore. For any sales queries, contact us at +1 (775) 404-5757. You can also email us at sales@avench.com. We will be happy to assist you.