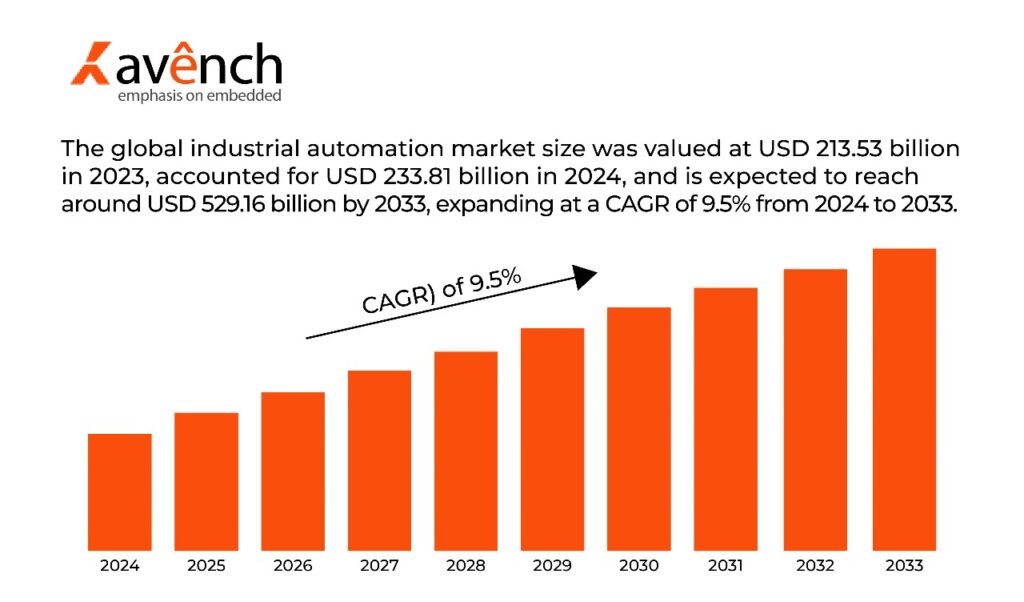

Time passed, and with it came industrial automation to serve as a backbone for boosting productivity, efficiency, and reliability in most industries. From the manufacturing side to logistics, the advanced technologies and the systems had changed the ordinary processes and paved the road for intelligent and responsive procedures. Here are 12 critical tips on mastering industrial automation with regard to projects related to embedded software projects, reliable systems, protocol communications, Linux customization, and assurance of quality.

1. Understanding What is Industrial Automation

Understand the concept of industrial automation before getting into details. Simply put, industrial automation refers to the use of control systems, computers, or robots in association with information technologies in handling different processes and machineries in an industry. It is a technology-based approach that tries to minimize human intervention, precision, and efficiency.

2. Choice of Industrial Automation Services

The industrial automation services to be chosen have an importance towards installing and running the systems successfully. Services might include consulting, system integration, maintenance, and support. Be sure the providers of the services have had proven delivery track records and also technical capabilities in any given technology to address the given needs.

3. Top Quality Industrial Automation Solutions

Industrial automation solutions of the highest quality are critical for achieving maximum performance and reliability. Such solutions include a wide range of technologies such as sensors, actuators, controllers, and software systems. When analyzing potential solutions, look at growth potential, compatibility with existing systems, and the ability to meet your long-term operational goals.

4. Utilize Industrial Automation Software

The key function of industrial automation software is to automate and facilitate system control. It will, therefore, cover a range that includes simple programmable logic controllers to more complex supervisory control and data acquisition systems. Ensure that the sort of software you choose should be user-friendly, able to scale quickly, and fit in well with other systems available in the facility.

5. Power Industrial Automation and Control Installation

Any automated operation has effective industrial automation and control systems as its backbone. These systems comprise hardware and software elements used to monitor and control industrial processes. The main components include PLCs, DCS, and HMIs. Carrying this out properly involves selecting the right components, arranging them correctly, and maintaining them regularly.

6. Implementing State-of-the-Art Industrial Automation Equipment

The selection of appropriate industrial automation equipment is critical to the success of your automation initiatives. The equipment includes sensors, actuators, controllers, and communication devices. When choosing the equipment, consider factors such as accuracy, durability, compatibility with other systems, and the ability to work under harsh industrial environments.

7. Developing Reliable Embedded Software Projects

Embedded software is the driving force behind most industrial automation systems. Reliability, real-time performance, and scalability are key aspects while developing embedded software projects. Utilize strong development methodologies like Agile or DevOps, ensuring continuous integration, testing, and delivery of quality software.

8. Reliable Embedded Systems

The embedded systems in an industrial process will maintain a consistent and accurate industrial operation only if they are reliable. When achieving reliability, follow best practices in hardware design. Such best practices include high-quality components, redundancy, and rigorous testing. Your software must also be fault-tolerant and recover from errors gracefully.

9. Industrial Protocol Communications

Key is effective communication among various components of an automation system. Industrial protocol communications, like Modbus, Profibus, and Ethernet/IP, ensure efficient data transfer between devices. To master these protocols requires the knowledge of their specifications, configuring network settings, and ensuring data integrity and security.

10. Embedded Linux Customization for Industrial Applications

The flexibility, scalability, and cost-effectiveness of the system are significant advantages of industrial automation systems due to embedded Linux customization. Customizing Linux means tailoring the kernel, device drivers, and user-space applications according to your industrial environment. So, your customization should mainly focus on real-time performance, security, and easy maintenance.

11. Implementing Quality Assurance in Embedded Projects

Quality assurance (QA) is an important part of embedded software development. Quality implementation through QA involves unit tests, integration tests, and system tests. Implement these using automated testing tools that can provide full coverage with the detection of issues at the earliest stages of the development process. Also, implement code reviews on a regular basis and follow the guidelines of the industry.

12. Continuous Learning and Adaptation

The field of industrial automation is always changing, and new technologies and methodologies appear every day. To keep ahead, one should embrace continuous learning and adaptation. Attend industry conferences, join online forums, and complete certifications to keep your skills and knowledge updated. Adopt an creative culture within your organization to keep improving and being competitive.

Conclusion

Mastering industrial automation requires the combination of technical expertise, strategic planning, and commitment to continuous improvement. It is in the understanding of the basics, investment in quality solutions, and following best practices that will unlock the full potential of automation technologies and drive significant improvements in your operations. Whether you are developing embedded software projects, implementing reliable systems, or optimizing communication protocols, these 12 tips will guide you toward success in the dynamic world of industrial automation.

What do you think about these top 12 tips and do you have any other suggestions or tips in mind, do comment below and check out our website for more information.

Avench is one of the leading , embedded systems development in usa to know more information for any sales queries, wait for no further contact us at +1 (775) 404-5757. You can also email us at sales@avench.com, or fill the query form in a website.