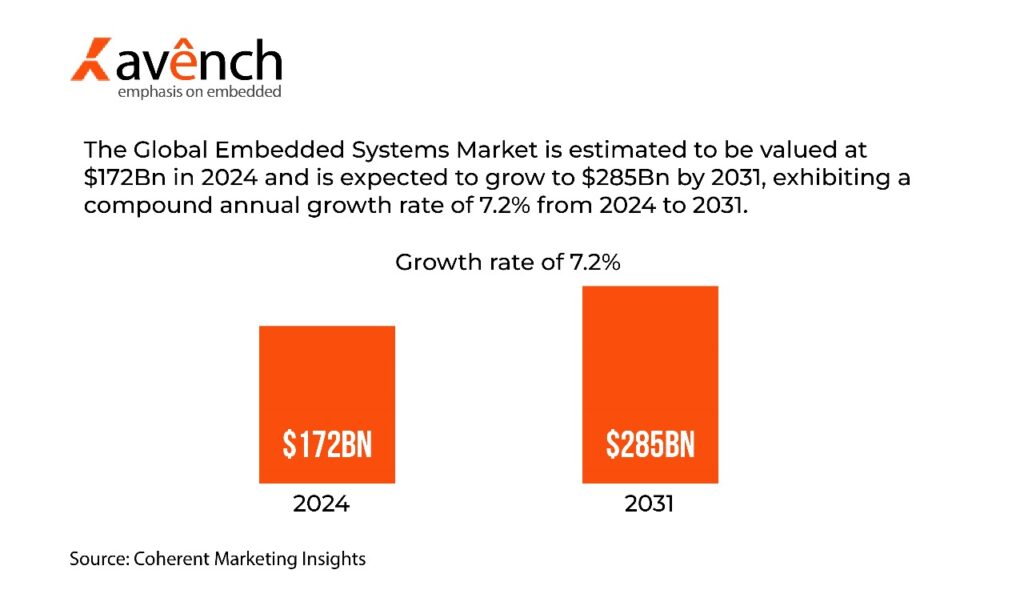

Embedded systems have always been the unsung heroes in the fast-paced world of technology, which has created a thrust towards innovation and efficiency across many industries. Today, companies all over the globe are seeking low-cost, yet reliable solutions for their needs in embedded hardware design. This guide takes the technicalities involved in embedded hardware design a bit deeper while giving insight into its relevance, various models, and outsourcing benefits through specialized Indian companies. Once you get to the end of this article, you will gain a complete understanding of how these models could change the operations of your business and your competitive advantage.

The Nature of Embedded Hardware Design

This process includes developing the physical parts constituting the embedded systems. The systems include numerous applications that run from consumer electronics and industrial automation. The overall design includes stages that are conceptual development, testing, and deployment; they guarantee the final product is geared toward specific performance criteria, reliability, and cost criteria.

Key components in the embedded hardware design

Microcontrollers and Microprocessors: These are the control units of any embedded system. They run through programmed instructions and control other parts of the system. Proper selection and integration of them can enhance the system’s performance.

Sensors and Actuators: These are the devices that collect data from the environment and perform actions based on the information processed. Their precision and reliability are vital for proper system functionality.

Power Supply Units: The power supply units are critical in ensuring a stable and reliable power source for the optimal functioning of embedded systems, especially in industrial applications.

Communication Interfaces: These modules allow data exchange between the embedded system and other devices or networks, thus enabling real-time monitoring and control.

The Role of Embedded Systems Hardware Design Services

Embedded system hardware design services take innovative ideas to functional products. These services involve a whole range of activities, including

Requirement Analysis: The needs and constraints of the project should be understood clearly for the design to be successful.

System Design: Develop detailed blueprints and schematics of the embedded system to ensure that all the components work together.

Prototyping and Testing: Prototyping and rigorously testing prototypes for the desired specifications and performance.

Production Support: Support to the manufacturing and assembly of the final product to ensure quality and reliability.

Through these services, companies can make sure their embedded systems are designed with the highest standards and meet all the technical and regulatory requirements.

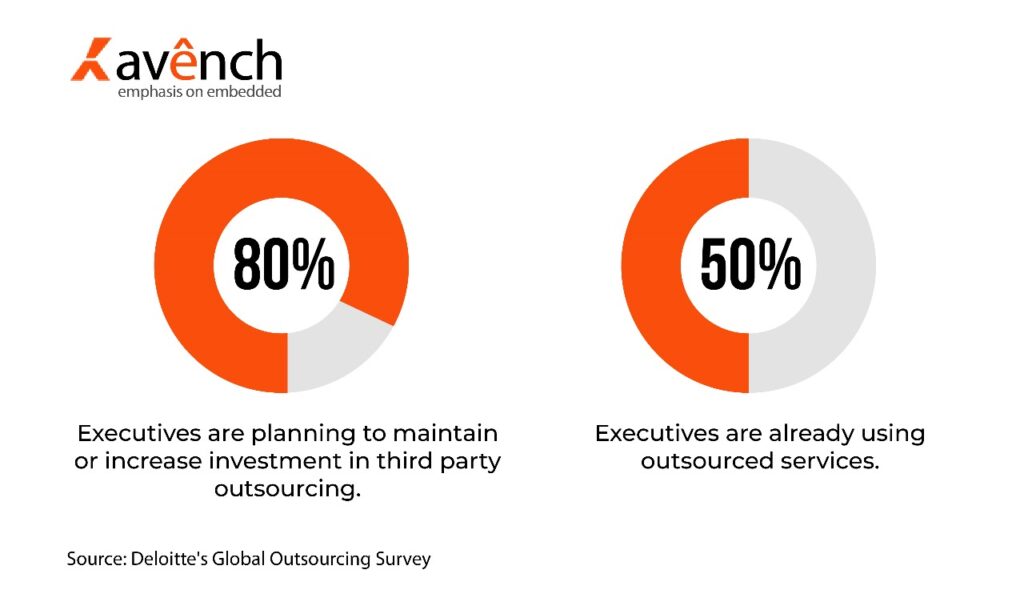

Advantages of Outsourcing Embedded Hardware Design

There are several advantages that outsourcing embedded hardware design and development to specialized companies gives to businesses in the USA and Europe. Here are some of the benefits:

Savings in Labor and Production Costs: Outsourcing to countries like India can significantly reduce labor and production costs without compromising on quality.

Access to Expertise: Specialized embedded hardware design companies have a lot of experience and technical know-how, so your project will be in the hands of experts.

Scalability: Outsourcing allows easy scalability of operations due to its response to the change in the market.

Focus on Core Competencies: Due to outsourcing, businesses focus on core competencies that lead to innovation and growth.

Impact of Embedded Hardware Design on Industrial Automation

Manufacturing and manufacturing procedures through integrated automation in industrial systems have increased significantly as far as the efficiency, accuracy, and safety aspects of manufactured items are concerned. Embedded in the industrial automation system provides machinery with real-time control, predict potential breaks through regular maintenance, and based on these decisions taken data. These systems also designed for harsh industrial environments while considering possible breakage and downtime reduction.

Embedded System Case Study Topics:

A leading manufacturing company in the USA was not doing well in its production line, and it had experienced frequent equipment failures and maintenance costs. Working with an embedded hardware design company from India, the company designed a custom solution.

The project involved the design and development of an embedded system that was able to monitor in real-time the health of critical equipment. Using state-of-the-art hardware design tools for embedded systems, the team designed an integrated system using sensors, microcontrollers, and communication interfaces.

The system gave real-time information on the performance of the equipment, hence foretelling when it needed to be serviced and less downtime.

Remarkable outputs:

30% fewer breakdowns in equipment

25% savings in maintenance cost

Efficiency improvement and product quality through better production.

This case study emphasizes the revolutionary effect of embedded systems on industrial automation and underscores the importance of cooperation with experienced design companies.

The Embedded Software Development Cycle

Though hardware forms the basis of the embedded system, it is no less indispensable to the functionality of these systems. The following phases comprise the life cycle for developing embedded software:

Requirement Analysis: Requirements are defined based on the functionality and performance criteria of the system.

Design: It includes software architecture and design specifications for ensuring the robust and efficient development of software.

Implementation: Design specifications are used for coding and integration that are followed under best practices for the development of embedded software.

Testing: Testing will be quite strict and performed based on verification standards as regards software standards and whether software behaves the way it was supposed to.

Release and Support: The release of software as well as continued support as well as updates for further reliability and performance over long periods.

Embedded software development companies play a vital role in the entire process, and the robustness, efficiency, and security of the software are ensured. This ensures that the embedded systems work well and that the systems are properly optimized.

Turnkey models and Offshore Development Centers (ODCs)

The companies can also benefit from turnkey models and Offshore Development Centers (ODCs) besides outsourcing specific design services.

The turnkey model is an outsourcing of the entire project, from conceptualization to final deployment to a specialized company.

The following are some advantages of this model:

End-to-End Solutions: All aspects of the project are handled by the outsourcing partner so that the whole thing comes together seamlessly and is delivered.

Reduced Risk: The outsourcing partner assumes the risk of project success, which reduces the risk for the client.

Faster Time-to-Market: The project would be taken care of by an experienced partner, allowing companies to accelerate their timelines and get products to market sooner.

Offshore Development Centers, on the other hand, mean establishing a dedicated team in another country to take care of some specific aspects of a project. The model offers several benefits:

Cost Benefits: Labor is cheap in countries like India, so it’s easy for a company to cut down on development costs.

Dedicated Team: One of the features of working with the ODC is that a dedicated team of expertise is offered for an assignment and this is stamped with high focus and commitment.

Scaling up/Scaling down: Based on the project’s requirement, ODCs provide opportunities to scale up or down the team to optimize the usage of resources.

Both models offer great alternatives to companies who want to outsource their embedded system projects and take advantage of global expertise so they can realize their business goals.

IoT Development and Its Role in Embedded Systems

IoT is a transformative force in the domain of embedded systems that lead to the development of networked devices. These devices can be highly interactive and share information smoothly. The process of developing an IoT project encompasses many critical stages, thereby enabling smart, efficient, and secure solutions.

Major Phases in IoT Development

Device Design: This is about the design of the actual hardware. This hardware will consist of a sensor, a microcontroller, and their capability to collect and then transmit this data. So, they have to be efficient, reliable, and able to process data in real time.

Software Development: This involves developing the software code that will allow IoT devices to perform specific tasks. It enables the development of firmware for the devices as well as applications in processing and later analysis of the data.

Data Integration: The data collected by the IoT devices can be effectively integrated, analyzed, and put into action. It concerns the configuration of databases, data processing algorithms, and analytics tools.

Security: Develop security to protect data and the integrity of the IoT system. This would include encryption, authentication, and regular security updates to avoid breaches.

Companies can use IoT development to come up with innovative solutions that can improve efficiency and drive growth in various sectors through better decision-making. For example, IoT-enabled embedded systems in manufacturing industries monitor equipment health and predict the need for maintenance while optimizing production processes.

Exploring Embedded Systems in Industrial Automation

Embedded systems in industrial automation are the backbones that ensure accuracy in control and monitoring of machine performance. They are usually designed to work in unfavorable conditions, thus ensuring efficiency and durability.

Key Industrial Automation Applications of Embedded Systems

Real-Time Monitoring: Embedded systems collect and analyze information from sensors in real time in order to provide valuable insights into equipment performance and operational efficiencies.

Predictive Maintenance: Through an analysis of data trends about the embedded system, the time for maintenance can be forecast, thus avoiding untimely breakdowns and any resultant downtime.

Automated Control: Through an embedded system, it is possible to give the machinery or processes automatic control whereby there is optimum performance with too much interference from man.

The Embedded Software Development Life Cycle

The embedded product development life cycle is a comprehensive process that guides the development process for the robust, efficient, and secure software of an embedded system. All the stages are very crucial in delivering quality software that satisfies the very needs of the project.

Stages of Embedded Software Development Life Cycle:

Requirement Analysis: The process of gathering detailed specifications for the functional and performance requirements of the software. This involves defining the scope of the project.

Design: The process of creating a comprehensive software architecture and design plan. It involves defining modules, interfaces, and data flow within the system.

Implementation: This is the process of implementing the design specifications in the source code. Here, while writing the code, one is supposed to follow the coding standards and best practices for efficiency and reliability.

Testing: Comprehensive testing that will ascertain the software has met all the specified requirements and behaves as anticipated. This comprises unit testing, integration testing, system testing, and acceptance testing.

Deployment and Maintenance: Deployment of the software in the target environment along with providing continuous support and updates. The activities of maintenance include bug fixes, performance enhancement, and security updates.

Engagement with skilled embedded software development company’s will ensure that each phase of the life cycle is managed appropriately. This way, the end product is quality software that enhances the functionality and reliability of embedded systems.

Role of Embedded Hardware Design Tools

Specialized tools for designing and developing embedded systems guarantee accuracy, efficiency, and quality. Any embedded hardware design tool falls in the range of software and hardware solutions that are applied during the entire process of designing and developing.

Key Embedded Hardware Design Tools:

CAD Software: this includes Altium Designer, Eagle, and KiCad. These tools are used to draw high-level schematics and layouts on embedded systems.

Simulation Software: MATLAB and Simulink are simulation software packages that enable engineers to simulate the behavior of embedded systems before actual prototypes are created, so possible problems are detected in the early stages of design.

PCB Design Tools: OrCAD and Allegro are some of the most popular tools that are used to design and test printed circuit boards to meet the desired specifications.

Debugging Tools: The debuggers and emulators like JTAG and SWD provide real-time debugging capabilities, which are the most important in identifying and fixing errors within an embedded system.

The tools can be used by engineers to streamline the process of design, reduce development time, and deliver high-quality standards for embedded systems.

Turnkey Models and Offshore Development Centers (ODCs)

Turnkey models and Offshore Development Centers (ODCs) are strategic benefits for any organization that is looking to outsource its projects.

Turnkey Models:

Comprehensive Solutions: It’s an outsourced solution for the entire project from conceptualization to the final deployment by a specialized partner.

Risk is all transferred to the shoulders of the partner; thus, it does not land on the client’s side.

Faster Development: It accelerates the timelines in development through experienced partners and thus facilitates faster time-to-market.

Offshore Development Centers (ODCs):

Cost Efficiency: ODCs benefit from low labor costs in countries like India, thus lowering overall development costs.

Dedicated Teams: ODCs offer dedicated resources, which are fully dedicated to the client’s project and thus focus their attention on that project.

Scalability: ODCs offer scalability in terms of resource addition and subtraction according to project needs, thereby optimizing efficiency and resource utilization.

Using these models, companies can achieve global expertise at a reduced cost while fulfilling their business goals.

Conclusion: Embracing the Future with Embedded Hardware Design

As technology continues to advance, the importance of embedded hardware design and its related services cannot be overstated. From enhancing industrial automation to driving IoT innovation, embedded systems are at the forefront of modern technological advancements.

For companies in the USA and Europe, understanding the value of outsourcing to specialized embedded hardware design companies based in India can provide a significant competitive edge. By leveraging global expertise and models like turnkey projects and ODCs, businesses can achieve cost-effective, reliable, and innovative solutions that drive growth and success.

As we move forward, the synergy between hardware and software development will continue to shape the future of embedded systems, transforming industries and improving the quality of life. Embracing these advancements will enable companies to stay ahead in the competitive landscape, delivering superior products and services to their customers.

For experts in the electronics industry, staying informed and educated about these trends is crucial. By understanding the potential and benefits of embedded hardware design, they can make strategic decisions that propel their businesses forward.

Avench is one of the leading embedded systems development in usa, to know more information for any sales queries, wait for no further contact us at +1 (775) 404-5757. You can also email us at sales@avench.com, or fill the query form in a website.