The Internet of Things (IoT) is now very much a major force that is changing the face of industrial automation. Businesses across the world are getting very high ROIs by integrating the IoT with industrial processes. This is powered by massive applications of IoT in industrial automation, typically giving greater efficiency at lower costs and with enhanced decision-making ability.

We dig into the details of how measurable business value in industrial automation is powered by the IoT.

We dig into the details of how measurable business value in industrial automation is powered by the IoT.

The Role of IoT in Industrial Automation

The role of IoT devices in industrial automation cannot be overstated. IoT devices and systems collect and analyze data in real time, providing insights that were previously unattainable. These insights have the capability of letting companies optimize their operations, leading to improved productivity and cost savings.

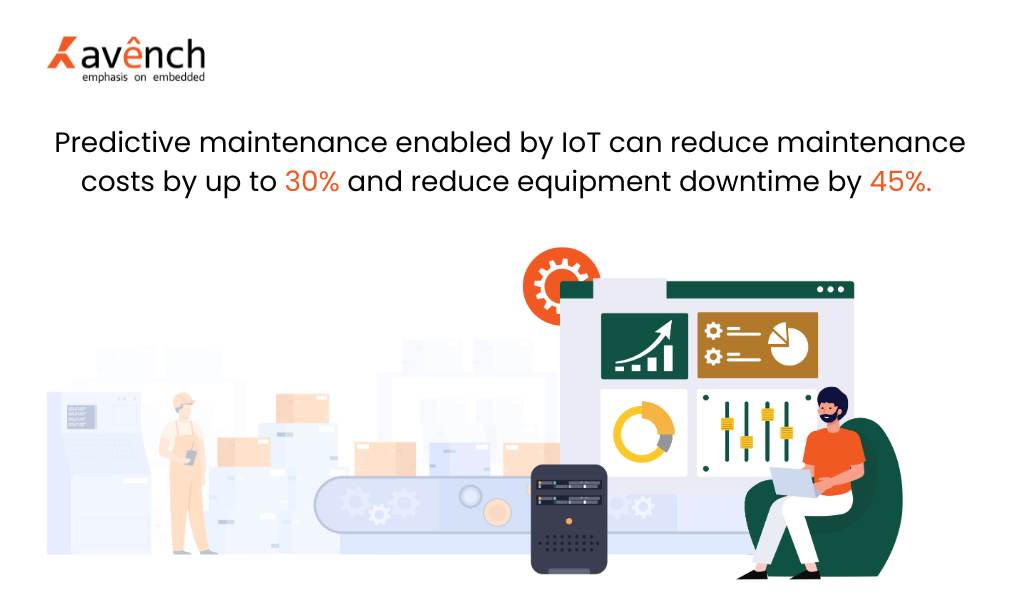

One of them is the predictive maintenance aspect. According to most maintenance schedules, this is generally done after fixed intervals. This may result either in routine maintenance or in equipment failure when maintenance is needed. IoT sensors monitor the condition of the machinery and find out the root cause for when maintenance might be required. This IoT-based industrial automation project can greatly reduce downtime and maintenance costs.

Key Applications of IoT in Industrial Automation

Several critical IoT applications in industrial automation are driving this ROI revolution. Here are some of the most impactful ones:

1. Predictive Maintenance

This, perhaps, is one of the most popular applications of IoT in Industry 4.0: Predictive Maintenance. As a result of sensors and data analytics, it is possible to predict equipment failure before this happens. Such an approach minimizes downtime and also expands the lifespan of machinery, which results in huge cost savings.

2. Monitor and Control Remotely

It makes it possible for IoT to monitor and control remotely as pertains to the length of industrial processes. This comes in quite useful in the vast-scale operations and dangerous environments as seen in the applications of IoT in the oil and gas industry. Remote monitoring assures safety and raises efficiency besides curtailing Trotter on-site staff.

3. Energy Management

Consumption of energy by the industry is one of the biggest operational expenses. Through IoT solutions, one gets adequate insights into patterns of energy usage and thereby helps in the optimization of energy consumption that not only cuts down the costs but also promotes sustainability to a large extent.

4. Supply Chain Optimization

It provides real-time movement of goods. These iiot applications in the industrial segment ensure automated supply chain management, which will work towards on-time deliveries and reduce inventory costs and thus improve the general efficiency of the supply chain.

Use Cases of IoT in Various Industry Domains

Use Cases of IoT in Various Industry Domains

The impact of IoT in industrial automation spans across various industry domains, each benefiting uniquely from IoT implementations. Here are some notable use cases:

Manufacturing

IoT offers real-time monitoring of the production line, hence ensuring that the machines are performing optimally. There has been improved productivity and even reduced defect rates. IoT integration also allows for flexible manufacturing whereby the production process is adjusted to demand changes within the shortest time.

Oil and Gas

Applications of IoT in the oil and gas industry are pipeline integrity monitoring, drilling operation optimization, and the management of assets in remote locations. IoT eliminates spills and leaks and thus can improve environmental safety and reduce risks.

Agriculture

IoT in agriculture, otherwise known as Smart Farming relies on the use of sensors to gather information about soil conditions, weather patterns, and crop health to inform farmers on the decisions to make. The farmer will thereby increase yields as well as have resourceful use.

Logistics and Transportation

IoT contributes much to the logistics factor by facilitating the real-time tracking of goods and hence making the routes efficient. There will, therefore, be an efficient delivery of the products on time, which will save on cost and achieve customer satisfaction.

Industrial Automation Using IoT: Benefits and Challenges

While the benefits of industrial automation using IoT are clear, it is important to acknowledge the challenges that come with it. There would need to be substantial investment both in the integration of IoT systems as well as the technology and infrastructure to support them. Another area of major concern is data security and privacy, especially when sensitive information is at stake.

These, however, absolutely are the long-term ones. The organizations that have been able to inculcate this very IoT within their industrial processing claim that work has been much more efficient, the cost associated with work has gone down, and there has indeed been considerable improvement in product quality. Decision-making and strategic planning have been better as well due to insight from data-driven reports.

Future Outlook: IoT and Industrial Automation

The future of IoT applications in industrial automation looks promising. As technology moves to a higher level every day, one could expect applications and innovations to great proportions. The 5G networks will ensure that IoT has even faster data transmission speed and more reliable connections to enable the IoT applications and grant a person the features.

Also, additional development of AI and ML will go to complement IoT. These will allow for gaining even more profound insights and sophisticated automating capabilities, which will result in further increases in efficiency, productivity, and ROI.

Conclusion

IoT integration into industrial automation is much more than a trend. Instead, it is more about a fundamental shift-fast delivering, measurable business value. Through applications of the IoT in Industry 4.0, companies are finding new efficiency, cost savings, and operational excellence. While the technology continues to evolve, the potential for even greater ROI will only increase the IoT as an indispensable component of modern industrial automation.

Avench is one of the leading industrial iot gateway. For any sales queries, contact us at +1 (775) 404-5757. You can also email us at sales@avench.com. We will be happy to assist you.

Use Cases of IoT in Various Industry Domains

Use Cases of IoT in Various Industry Domains